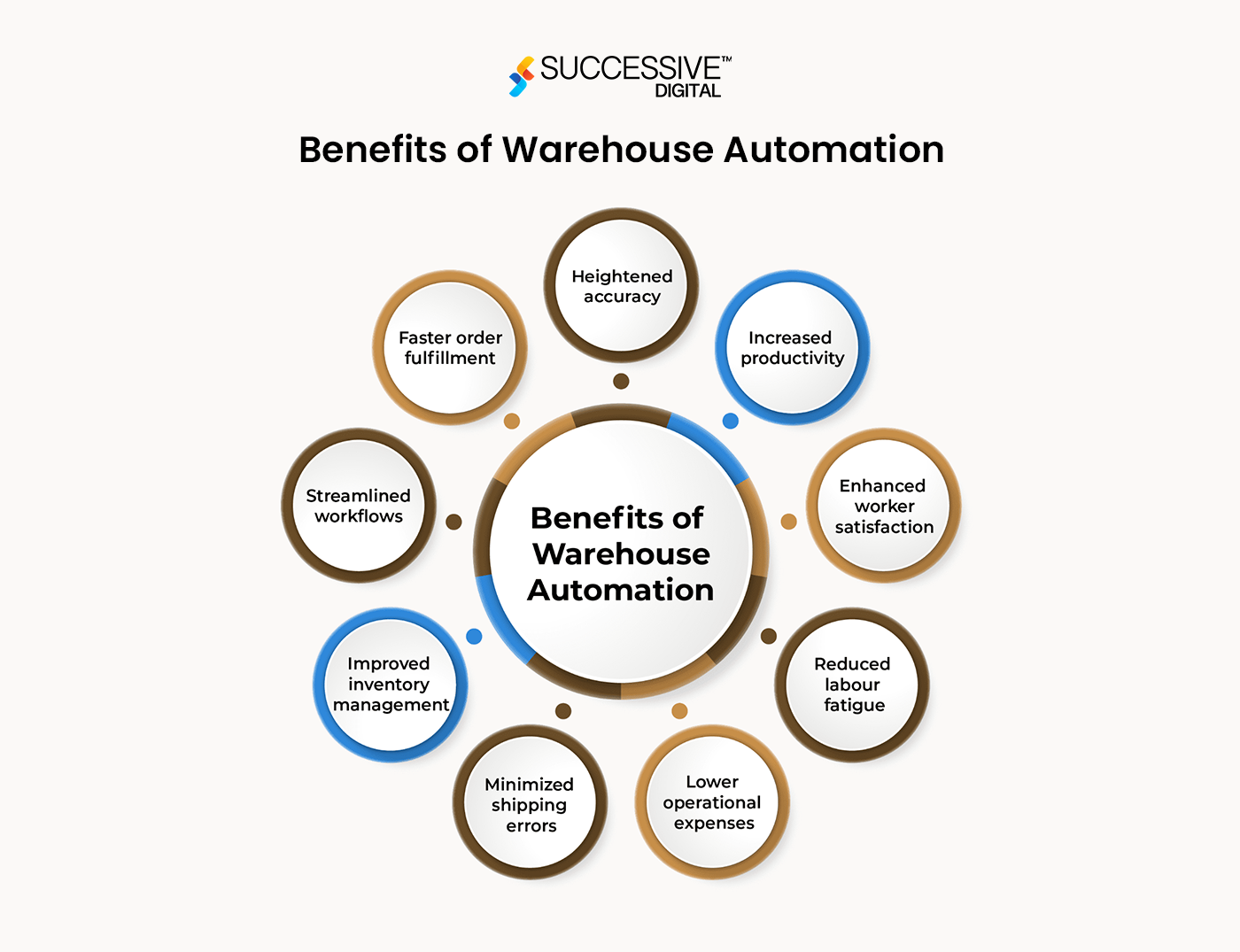

As companies attempt to meet the growing needs of e-commerce and just-in-time delivery, the complexity of handling warehouse management systems continues to become complex. Conventional warehouse management methods, which regularly rely on manually guided processes and paper-based monitoring, cannot meet the pace and accuracy required by modern logistics & distribution companies. This is where Warehouse management software (WMS) comes into play. This blog explores how adopting a WMS is not just a trend but a necessity for organizations aiming to thrive competitively in an increasingly customer-driven market.

-

Increased Cost Savings

Even though the initial funding for inventory management solutions can be huge, the long-term cost savings it affords can far outweigh the upfront expenses. By enhancing inventory accuracy, reducing labour costs, optimizing area utilization, and increasing operational efficiency, a WMS can lead to considerable cost reductions throughout the board.

Furthermore, the improved visibility and reporting features of a real-time inventory tracking allow businesses to perceive inefficiencies and areas for development, which are mainly related to financial savings. For instance, by analysing inventory turnover rates, businesses may also find out that high-selling goods are being overstocked, leading to useless carrying expenses at the time of peak demand. By adjusting stock levels primarily based on these data, the warehouse teams can reduce those charges and improve profitability.

-

Enhanced Inventory Accuracy

One of the key benefits of a warehouse management system is its capability to ensure correct inventory data records are followed. Traditional inventory tracking methods, including guide counting or spreadsheets, are susceptible to human error, which may result in discrepancies between actual inventory degrees and what is recorded. A WMS automates the stock tracking technique by utilizing barcode scanning, RFID technology, and actual-time information updates, ensuring that inventory statistics are always correct.

Accurate inventory data, made possible by warehouse automation, plays a crucial role in decision-making. It helps in determining the best time to reorder items or discontinue slow-moving products, thereby preventing stockouts or overstocking. This level of control is essential for maintaining optimal inventory levels and ensuring efficient warehouse operations.

-

Improved Order Fulfilment and Accuracy

Order fulfilment is a vital factor of warehouse operations, directly impacting customer experience and retention. Inventory management solutions streamline the order fulfilment process by way of automating tasks such as picking, packing, and delivery. By guiding warehouse workers through optimized routes and ensuring that the proper products are picked for each order, a WMS minimizes mistakes and increases order accuracy along with enhanced supply chain management.

This degree of precision is not only most effective but reduces the likelihood of returns and exchanges. It also enhances the supply chain management, allowing businesses to fulfil orders in greater speed.

-

Increased Productivity and Efficiency

Warehouse operations involve various duties, from receiving and storing stock to handling, packing, and dispatching orders. With a warehouse management gadget (WMS), these responsibilities can become more manageable and labour-intensive, central to inefficiencies and potential bottlenecks. A WMS automates and streamlines these techniques, extensively decreasing the time and effort required to hold them out.

For example, one of the key benefits of warehouse management system is its capability to optimize product placement, ensuring frequently picked goods are saved in handy regions to improve productiveness without difficulty. Moreover, a warehouse management software can automate the replenishment method, keeping inventory degrees consistent without the need for manual intervention. With the aid of automating ordinary obligations and refining workflows, a WMS permits a warehouse team of workers to pay attention to better-value activities, which include first-class manipulation and manner development, ultimately boosting universal operational efficiency.

-

Better Space Utilization

Warehouse space is an asset, and efficient use can lead to higher operating cost and increased productivity. A warehouse management software helps companies optimize their warehouse format by analysing inventory data and suggesting the most efficient storage locations for each product. This method, known as slotting optimization, ensures that goods are stored in a way that minimizes travel time and maximizes the use of available space.

Further to enhance supply chain management and storage efficiency, a WMS can also help identify underutilized areas in the warehouse. By looking for space utilization patterns, the system can suggest approaches to reorganize the warehouse layout to free up space for extra inventory or new product lines. This level of area optimization is particularly crucial for businesses experiencing peak demand or dealing with seasonal sales fluctuations.

-

Improved Labor Management

Labor is one of the most expensive costs in warehouse operations. A WMS can help businesses control their work force more effectively by optimizing resource allocation, tracking employee overall performance, and decreasing the time spent on manual duties. By automating routine responsibilities and offering real-time data on the workers’ productivity, a warehouse management software enables managers to make extra informed choices about staffing stages and workload distribution.

Additionally, a warehouse management system can help reduce the need for overtime or temporary labour by enhancing the performance of warehouse operations. With better exertion management, groups can decrease operating costs while preserving high degrees of productivity and accuracy.

Conclusion

A warehouse management system is essential for businesses aiming to streamline their warehouse operations and obtain a competitive advantage in market. With numerous benefits of warehouse management software, it can significantly improve the warehouse’s performance, productiveness, and value effectiveness by improving inventory accuracy, optimizing order achievement, and presenting extra visibility and scalability.